The Unseen Workforce Revolution

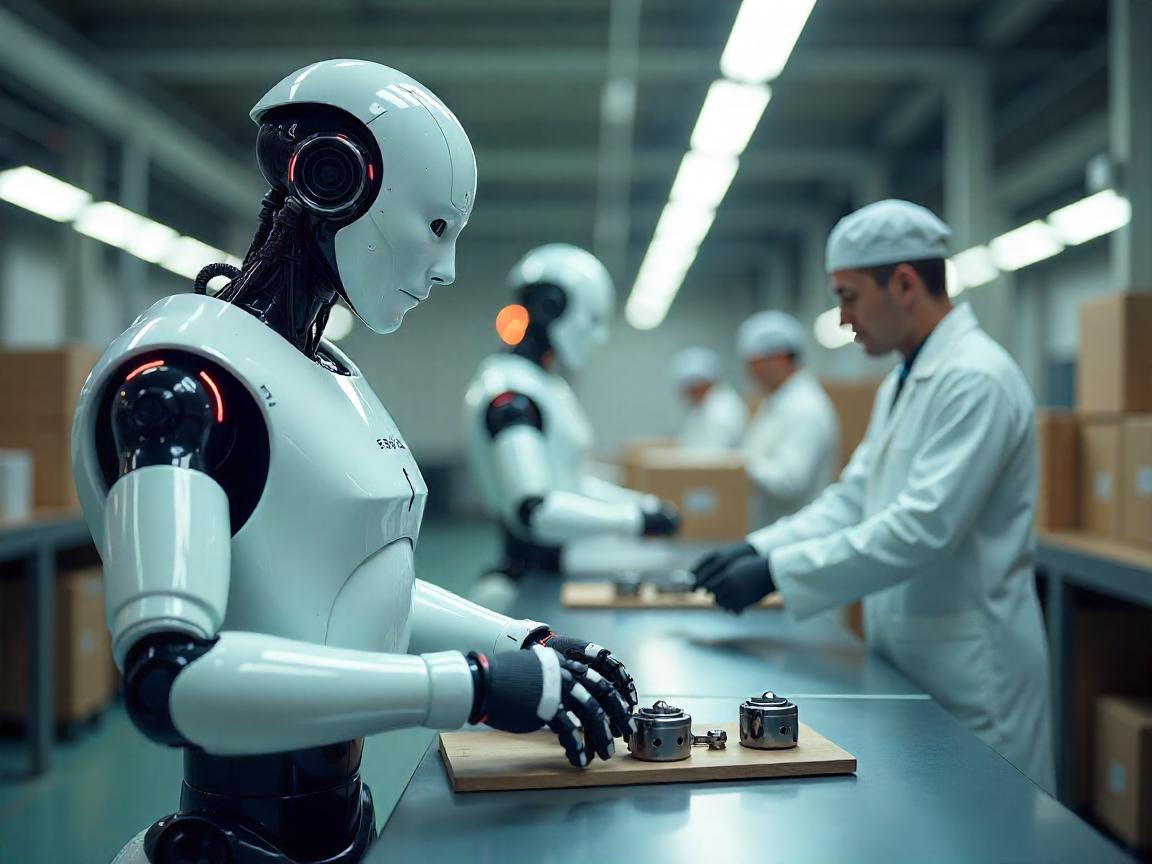

Today, you could enter a Tesla factory and meet an unexpected acquaintance a humanoid robot whose role involves a breeze of sorting parts, assembly lines, or even brittle tasks. It has nothing to do with a sci-fi movie, it is 2024 and Optimus 2.0 is already working by Tesla. AI-assisted chatbots and self-driving cars are the kind of headline-filling data toobs that the media can not get enough of but one automation transition is more real and encompassing than any of them, and that is the manufacturing-level shift. As IEEE Spectrum commented, Optimus bots are not an experiment in the laboratory anymore– they are currently under testing in Tesla factory in Fremont where they demonstrate the uncanny ability to perform real-life logistics.

So why humanoids? Conventional industrial weapons have reigned over the decades. The solution is the flexibility. Plants are created by humans, not wheeled bots, stairs are created, work benches are created, tools are created. Optimus 2.0 integrates with current work-flow without retrofit. And as Tesla is aiming to have a net price of less than 30,000, these robots might be less costly than a human worker to perform repetitive actions in the nearest future. This is the future of labor or is it another over-promized gadget? And now, let us get at the bottom of it.

Optimus 2.0: An Update on the Gimmick to Game-Changer

Take a recall of the unsteady and overly slow Optimus prototype of the year 2022? The new one is another animal. Thanks to the same neural nets that built Tesla its Full Self-Driving technologies, Optimus 2.0 also gets around in dynamic environments, varying the force of its grip as it goes along, and it will even right itself when it stumbles. The Robot Report mentions that its actuators have become 40 percent more energy efficient permitting longer work sessions without a recharge.

Yet, hardware is not the complete game. The magic juice of Tesla is its scalability. Although Figure AI is one of the startups that have had production bottlenecks, the manufacturing muscle of Tesla enables it to adopt Optimus bots to scale. Leakage regarding the usage of the machines implies that Foxconn is experimenting with them to assemble the iPhones, and BMW is experimenting with them by using them in automotive wiring one area where other robots do not bring in the needed portability.

Case Study: Optimus vs. the $500,000 Industrial Arm

This is where it is interesting. An extremely fast robotic arm manufactured by Fanuc can beat Optimus easily in one task but it is rigid. You change the product line and you are stuck with reprogramming hardware. Optimus? It can be changed to constructing battery packs by a software update.

- Price: The classic automation is more than half a million dollars a station. Optimus has a target below 30K.

- Flexibility: The units of Optimus in the Tesla gigafactory in Austin were repurposed overnight to perform quality assurance.

- Constraints: There is a maximum battery life on the nano of ~8 hours and the dexterity lacks that of a human hand.

This is not simply the replacement of workers but this is rather a restatement of efficiency. This way, Wired recently put it: Optimus does not excel at one thing, but it is decent at everything.

The Human Factor: Job Killer or Collaborative Tool?

Unions take precaution. The UAW already requested to know the company automation plans by Tesla, as they are afraid of massive staff reduction. Yet on a more subtle level, Dr. Karen Liu, an economist at Stanford in robotics, disagrees: history has indicated that automation has never taken away jobs in absolute states. Rather it lowers the wages in low-skilled occupations and adds niche techie job opportunities that the majority of the workers cannot attain.”

Take the example of warehouses of Amazon. More than 750,000 robots are employed there, but the number of people employed in the company also increased since someone should monitor the machines. The rub is not whether Optimus will provide employment, but whether savings would be invested back in upskilling programs. At this point, the evidence is slim.

What’s Next? Humanoid Boom of 2025

Tesla is not the only one. The purchase of Boston Dynamics by Hyundai may be considered an indicator of a competitor humanoid, and the Apollo robot by Apptronik is already negotiating with the world of logistic giant companies. Regulatory hell is on the way. OSHA does not have rules relating to humanoids sharing the workplace with humans, and liability is a legal quagmire.

The trend is however, irreversible. In 2025 Tesla envisages 1,000+ units of Optimus, and the leaked emails hint of “Optimus-as-a-Service” model in small factories. Think about the possibility of leasing a robot workforce on shift.

Final Thought: The Invisible Disruption

The awkward truth, as communicated in a recent event, is that Optimus 2.0 is not a far-fetched fantasy, it is a device that is being implemented today but there is little to say about it or turn the tide. Manufacturing revolution is not going to be televised; it will be taking place in the humble corners of those factories. Where men and humanoids robots will be come together to do their worst to each other as well as best.

Your analysis, what do you think? Should the government impose the so-called robot quotas in order to save jobs? Or does resistance no longer work? Post your ideas in the comments, and let us feel uncomfortable.